Anisoprint

Anisoprint

Core business

Anisoprint has developed a solution for the production of composite materials of a new generation. The company manufactures and supplies: equipment, software and materials for obtaining optimized parts from composite materials with required physical and mechanical characteristics. This activity is in strong development.

We are a team of researchers and engineers united by a common goal of introducing a new, globally demanded industrial manufacturing technology for optimized structures made of composite materials.

Products & services

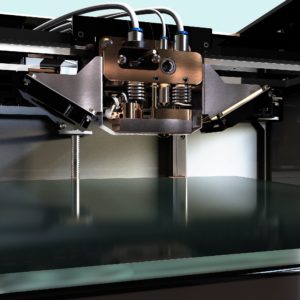

COMPOSITE FIBER CO-EXTRUSION (CFC) HARDWARE

Desktop Solutions

- CFC Printer Composer in 3 build areas: A4, A3 & A2

Industrial Solutions

- Industrial Printhead PH-5G2 and 5G3-HT for CFC and FFF printing based on 6-axial robot

- Prom-PT400 – industrial robot-based cell, 3-axial

MATERIALS

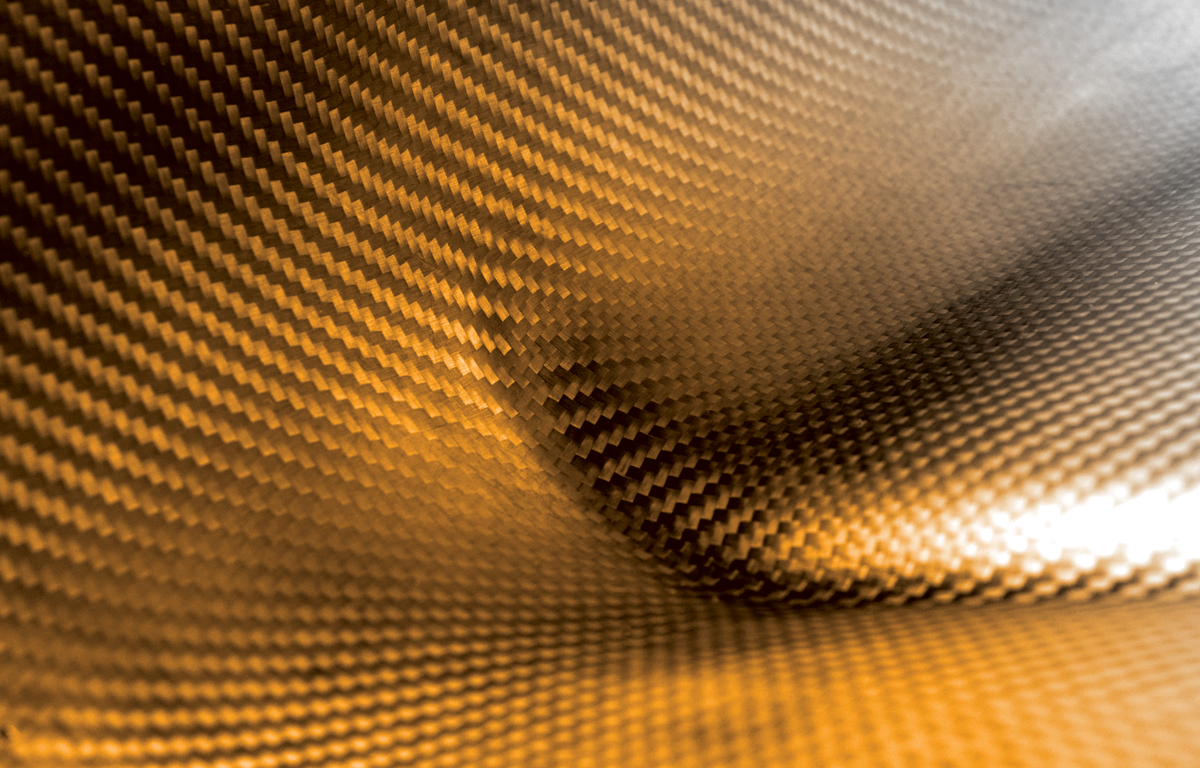

- CCF and CBF – Composite carbon and basalt fiber for CFC printing

SOFTWARE

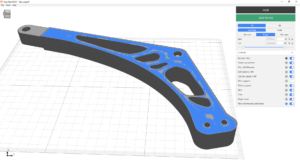

- AURA – Slicer software for CFC & FFF printing

Major Materials & Manufacturing projects

|

SALE&ADVANCEMENT |

Hardware | Software | Material |

|

Desktop |

Composer CFC Printers |

AURA |

Reinforcing fiber |

| Industrial | PH-5G,

Robot-based cells |

CAM software for multiaxial CFC-machines |

Technical / technological capabilities

We posess professional experience in additive manufacturing, design of composite structures in aviation & aerospace industries, industrial product development, as well as profound knowledge in materials science and composite engineering.

Anisoprint Composer with dual nozzle system allows to print using any thermoplastic materials reinforced with continuous fibers or unreinforced. Composer creates incredibly strong and lightweight parts (Х20 stronger than plastic, Х7 stronger that plastic compounds, Х4 lighter than titanium).

ADVANTAGES

- Open material system (use different polymers as matrix)

- Printing soluble supports

- Printing reinforced lattice structures

- Wide range of build volumes

- 30-50% lower material printing costs

- Non-cloud software

Main customers / collaborations

Customers: The Composite Technology Center (CTC) GmbH, BMW AG, Schunk Kohlenstofftechnik GmbH, HAGE Sondermaschinenbau GmbH & CoKG, Brightlands Materials Center/TNO, ERIKS Deutschland GmbH, Luxembourg Institute of Science and Technology, Technical University of Munich, Schaeffler Technologies AG, Fraunhofer Institute for Applied Polymer Research IAP, Bauhaus University Weimar, Tokyo Institute of Technology

Collaboration Projects within M-era.Net with: Technical University of Munich, Johannes Kepler University Linz – Institute for Constructional Lightweight Design, Johannes Kepler University Linz – Institute of Polymer Extrusion and Compounding, Kaunas University of Technology, Kompetenzzentrum Holz GmbH, HAGE Sondermaschinenbau & Co KG, PRIME aerostructures GmbH, PRIREVO e.U., Karfidov Lab LLC.

SAMIA 3D Project with Luxembourg Institute of Science and Technology within BRIDGES Programme.

Looking for

Investors, Funding, Partnerships, Export & Import support

Print this page Send by email